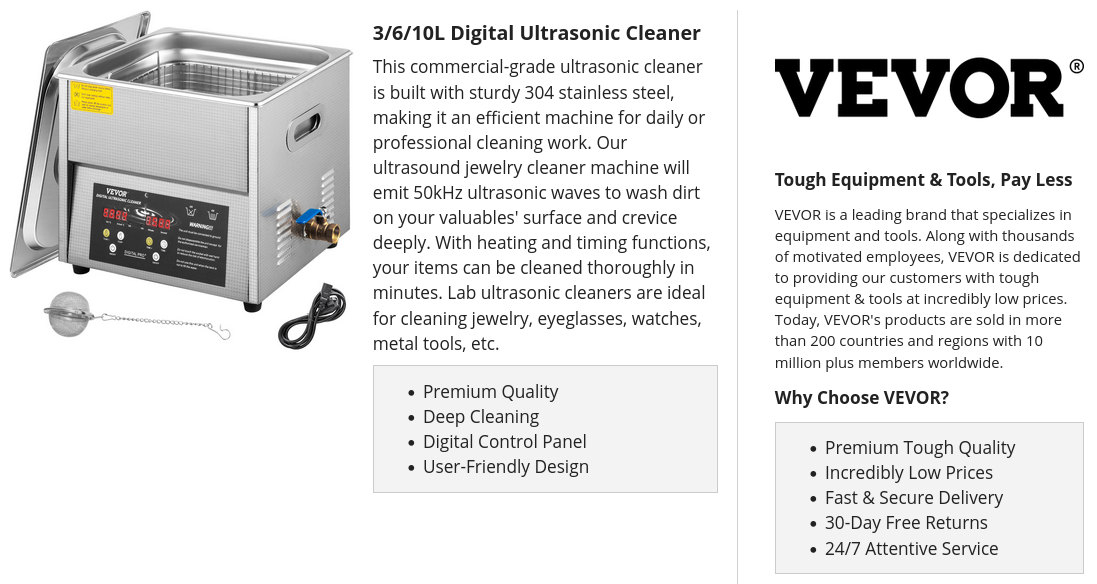

VEVOR 3L 6L 10L Ultrasonic Cleaner with Degassing Function, Premium quality, Deep cleaning, Digital control panel

Ultrasonic cleaners use the process of cavitation to clean objects. Cavitation is the formation and subsequent implosion of tiny bubbles in a liquid when subjected to high-frequency sound waves. Here's how it works:

- Transducer: The ultrasonic cleaner contains a transducer, which is a device that converts electrical energy into mechanical vibrations. These vibrations are typically in the ultrasonic frequency range, which is above the range of human hearing (usually around 50 kHz to several MHz).

- Formation of Bubbles: When the ultrasonic waves are applied to the cleaning solution, they create alternating high-pressure and low-pressure waves in the liquid. During the low-pressure phase, tiny vacuum bubbles or voids form in the liquid. These bubbles are very small, typically on the order of micrometers.

- Implosion of Bubbles: As the pressure waves cycle, the bubbles continue to grow during the low-pressure phase and then rapidly collapse or implode during the high-pressure phase. This implosion creates intense localized heating and shock waves. The temperature inside these collapsing bubbles can reach thousands of degrees Celsius, and the pressure can exceed 10,000 pounds per square inch.

- Scrubbing Action: The implosion of these bubbles near the surface of the object being cleaned creates a scrubbing action, dislodging dirt, grease, and other contaminants from the surface. This process reaches into crevices and areas that might be difficult to clean with manual methods.

- Rinsing and Drying: After the cleaning cycle is complete, the object is usually rinsed with clean water to remove any remaining cleaning solution or contaminants. Depending on the nature of the object and the cleaning solution used, it may also be dried using air or other methods.

Ultrasonic cleaners are commonly used in industries such as jewelry manufacturing, electronics assembly, automotive repair, medical device cleaning, and many others where precise and thorough cleaning is required. They are preferred for their effectiveness, efficiency, and ability to clean intricate or delicate objects without causing damage.

The degassing function in an ultrasonic cleaner is a feature designed to remove dissolved gases from the cleaning solution before the cleaning process begins. Here's how it works:

Purpose: Dissolved gases in the cleaning solution can interfere with the effectiveness of the ultrasonic cleaning process. These gases can form bubbles during cavitation, reducing the efficiency of the cleaning action. Additionally, degassing helps to ensure consistent cleaning results by removing any air pockets that might be trapped within the solution.

Operation: When the degassing function is activated, the ultrasonic cleaner operates at a lower frequency for a period of time. This lower frequency creates larger cavitation bubbles, which rise to the surface of the solution more easily. As these bubbles rise, they carry dissolved gases with them, effectively degassing the solution.

Timing: The duration of the degassing cycle depends on the specific design of the ultrasonic cleaner and the volume of the cleaning solution. Typically, degassing cycles can last anywhere from a few minutes to several tens of minutes.

Benefits: Degassing the cleaning solution before starting the cleaning process helps to improve the efficiency and effectiveness of ultrasonic cleaning. It ensures that the cavitation bubbles formed during cleaning are not hindered by trapped gases, resulting in more thorough and consistent cleaning results.

VEVOR Ultrasonic Cleaner with Degassing Function

PREMIUM QUALITY - Tank Size: 3/6/10L(0.8/1.59/2.64 Gal); Heating Power: 100/200/250 W; Ultrasonic Power: 120/180/240 W. This ultrasonic cleaner machine is constructed with sturdy 304 stainless steel, ensuring no water leakage and long service life. An extra basket is available to decrease collision between sharp items and the tank.

DEEP CLEANING - 50kHz frequency and industrial-grade transducers allow the ultrasonic jewelry cleaner to clean small items with complex construction or irregular shape easily. The degassing function protects the stuff from oxidation or other chemical reactions with the air during the cleaning.

DIGITAL CONTROL PANEL - The jewelry cleaner ultrasonic machine features a digital control panel, with an adjustable timer (0-30 min) and heater (0-176℉/0-80℃) displayed on LCD. A heating function can effectively soften and dissolve oil and wax stains, thereby improving the cleaning effect.

USER-FRIENDLY DESIGN - This commercial ultrasonic cleaner with a heater is designed for better customer use. Four anti-skid rubber feet keep the machine stable during operation. The drainage system with a valve at the bottom is convenient to discharge residual water and keep the area clean.

EXTENSIVE APPLICATION - Having passed CE certification, our heated ultrasonic cleaner is ideal for commercial, industrial, and residential use. The machine is suitable for dental clinics, hardware stores, scientific laboratories, jewelers, optical shops, watchmakers, antique dealers, etc.

Date published: 08 Apr. 2024

Fruit Vegetables Herb Drying Machine, Dried Fruit Vegetables Herb Drying Machine Household MINI Food Dehydrator

Making dried fruits, vegetables, and herbs at home can offer several benefits: Control Over Ingredients: When you make dried fruits, vegetables, and herbs at home, you have complete control over the ingredients used. You can choose organic... read more

Stainless Steel Flatware Cutlery Set Service, CEKEE 49-Piece Silverware Set with Organizer

To keep your cutlery set shiny and looking as good as new, here are some tips: Hand Washing: While some cutlery sets may be dishwasher safe, hand washing is gentler and helps preserve their shine. Use warm water and a mild dish soap to clean... read more

Hand Tool and Socket Set, CRAFTSMAN Mechanics Tool Set, 102 Piece Hand Tool and Socket Set

For small repairs around the home, having a few essential hand tools can make tasks much easier. Here are some of the most useful hand tools for home small repairs: Screwdriver Set: A set of screwdrivers with various head types (flathead and... read more

I found this product on aliexpress.com

I found this product on aliexpress.com